Cat:Weldless Chain

Weldless Sash Chain

A sash chain is a type of chain that is commonly used in windows to support and counterbalance the w...

See Details

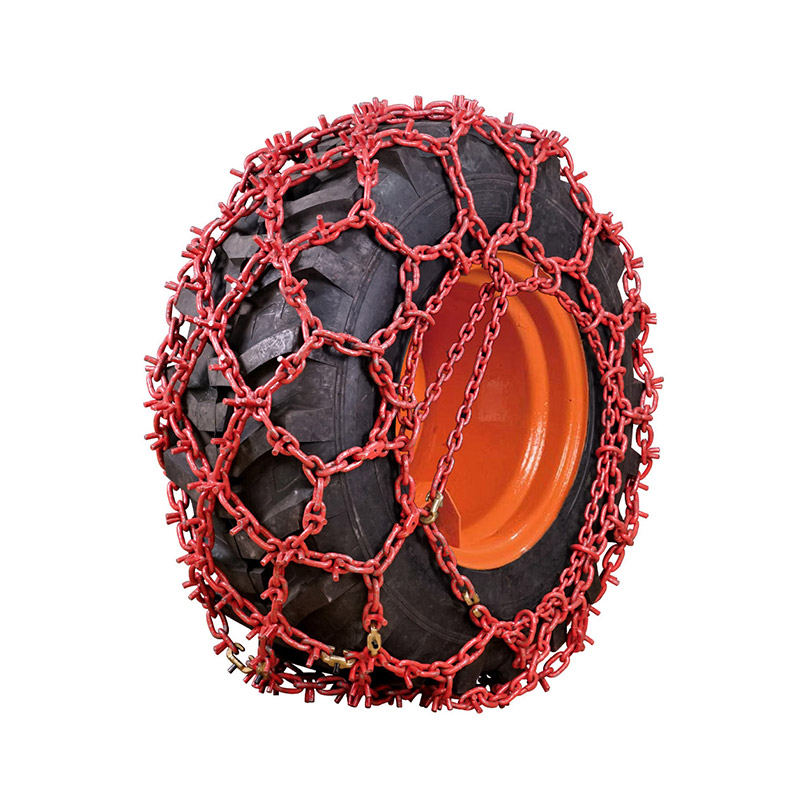

Heavy equipment tire chains are essential for ensuring reliable traction and stability in challenging terrains. These chains are specifically designed to provide extra grip and traction, allowing heavy machinery to operate safely and efficiently in difficult conditions such as snow, ice, mud, or steep slopes.

The primary function of heavy equipment tire chains is to enhance traction. These chains consist of multiple cross-sectioned metal links that are connected together and wrapped tightly around the tires. The metal links dig into the terrain, creating traction points that prevent the tires from slipping or spinning. This increased traction allows the heavy equipment to move forward or backward smoothly, even on slippery surfaces.

Chains dramatically improve stability by providing additional support and weight distribution. The heavy equipment tire chains effectively spread the weight of the machinery over a larger surface area, reducing the risk of sinking into soft ground or losing control on uneven terrain. This additional stability ensures that the machinery remains balanced and prevents accidents that could result from tipping over or getting stuck.

When heavy equipment is operating in snowy or icy conditions, tire chains are particularly crucial. Snow-covered or icy surfaces significantly reduce the friction between the tires and the ground, making it bad difficult for heavy machinery to gain traction. By using tire chains, the metal links bite into the ice or snow, helping to eliminate the slippery surface and enabling the equipment to move forward with greater control.

In addition to allowing safe operation, heavy equipment tire chains also minimize wear and tear on the tires. Working in challenging terrains without chains can cause excessive tire wear and reduce the overall lifespan of the tires. The chains act as a protective layer that shields the tires from direct contact with sharp rocks, rough surfaces, and abrasive elements present in difficult terrains. This helps to extend the life of the tires and reduces the need for frequent replacements, ultimately saving money for equipment owners and operators.

Heavy equipment tire chains are made using high-quality materials that are resistant to harsh conditions. The metal links are typically constructed from alloy steel, which provides durability and strength to withstand the immense pressure and stress exerted on them during operation. Moreover, these chains are designed to fit securely around the tires, ensuring that they remain in place even during high-speed movements or sudden changes in direction.

Proper installation and maintenance of heavy equipment tire chains are essential to ensure their effectiveness. Chains should be correctly positioned and tightened to avoid any slippage during operation. It is crucial to regularly inspect the chains for signs of wear, such as broken or bent links, and replace them when necessary. Inadequate maintenance can not only compromise the traction and stability provided by the chains but can also result in damage to the heavy machinery or pose a safety risk to operators and bystanders.

In conclusion, heavy equipment tire chains are instrumental in providing reliable traction and stability in challenging terrains. These chains enhance traction, improve stability, minimize tire wear, and ensure safe operation even on difficult surfaces such as snow, ice, mud, and steep slopes. Regular maintenance and proper installation are vital to maximize the benefits provided by tire chains. With their valuable contributions, heavy equipment tire chains enable efficient and secure operations in various working conditions.

A sash chain is a type of chain that is commonly used in windows to support and counterbalance the w...

See Details

These chains are designed for use on cars having minimal clearance availability These chains are des...

See Details

Double-duty regular twist link chains offer twice the number of cross chains putting more traction b...

See Details

A single jack chain is a type of chain that is commonly used for light-duty applications such as han...

See Details

A double-loop chain is a type of chain that consists of individual links that are joined together to...

See Details

A sash chain is a type of chain that is commonly used in windows to support and counterbalance the w...

See Details

These chains are designed for use on cars having minimal clearance availability These chains are des...

See Details

Double-duty regular twist link chains offer twice the number of cross chains putting more traction b...

See Details

A single jack chain is a type of chain that is commonly used for light-duty applications such as han...

See Details

A double-loop chain is a type of chain that consists of individual links that are joined together to...

See Details

A sash chain is a type of chain that is commonly used in windows to support and counterbalance the w...

See Details

These chains are designed for use on cars having minimal clearance availability These chains are des...

See Details

Double-duty regular twist link chains offer twice the number of cross chains putting more traction b...

See Details

Zhejiang Pujiang Bohu Chain Stock Co., Ltd. is a modern chain manufacturer integrating production, development, trade and service.

Phone: +86-18867178190

Phone: +86-17280971580

Tel: +86-579-84201119

Fax: +86-579-84201121

E-mail: zjpj@bohu.com

Add:No.565 Yatai Road, Pujiang, Zhejiang, China.

Tik tok

Public account

Mobile site

English

English 中文简体

中文简体